Product Categories

Featured products

Recent Articles

Zone 2 air compressor is a special air compressor used in coal mines and other mines to improve the safety performance of air compressors. Zone 2 air compressor is used for all electrical systems, switches, etc. of air compressor motors, control system electrical, display screens, etc. The parts of gas generator that may cause sparks must be explosion-proof. Simply put, the explosion-proof air compressor on AC alternator is an air compressor that cannot cause an explosion. Air compressor explosion protection for lighting tower is not only about motor explosion protection, electrical explosion protection for resistive load bank is more important, you think, if underground coal mines catch fire or explode due to air compressors, you only need motor explosion protection is not enough. There are few domestic manufacturers that can produce explosion-proof air compressors, and they need to have certificates such as “Safety Mark Certificate” to produce. The model, displacement, pressure, etc. of the air compressor must have a unique certificate. Coal mines or chemical systems are more stringent and may require explosion isolation. This is a diesel water pump technology to prevent the spread of explosions.

Zone 2 air compressor is a special air compressor used in coal mines and other mines to improve the safety performance of air compressors. Zone 2 air compressor is used for all electrical systems, switches, etc. of air compressor motors, control system electrical, display screens, etc. The parts of gas generator that may cause sparks must be explosion-proof. Simply put, the explosion-proof air compressor on AC alternator is an air compressor that cannot cause an explosion. Air compressor explosion protection for lighting tower is not only about motor explosion protection, electrical explosion protection for resistive load bank is more important, you think, if underground coal mines catch fire or explode due to air compressors, you only need motor explosion protection is not enough. There are few domestic manufacturers that can produce explosion-proof air compressors, and they need to have certificates such as “Safety Mark Certificate” to produce. The model, displacement, pressure, etc. of the air compressor must have a unique certificate. Coal mines or chemical systems are more stringent and may require explosion isolation. This is a diesel water pump technology to prevent the spread of explosions.

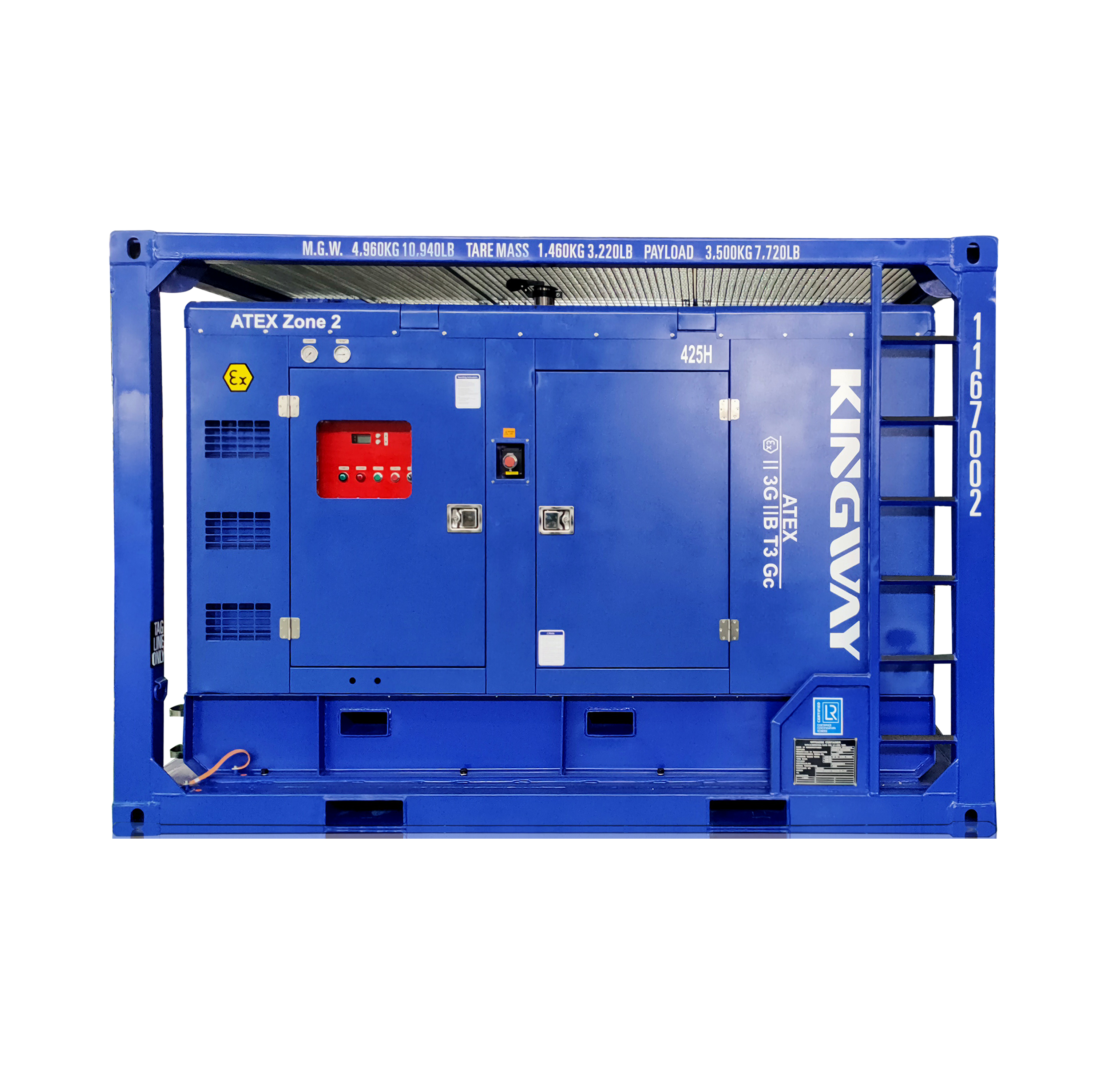

Diesel-powered generator sets are designed for use in Hazardous Area (Zone 2) and are installed in a DNV certified 2.7-1 Skid frame enclosure. They generate 250KVA @ 0.8 pf, 400VAC, 3 Phase +Neutral, with an output of 50HZ/60HZ.

Generator sets powered by diesel for use in Zone 2 Hazardous Areas, are installed within a DNV-certified 2.7-1 Skid frame enclosure. These sets produce 100KVA @ 0.8 power factor, 400VAC, 3 Phase +Neutral, with a 50HZ output.

Diesel generator sets fueled by diesel for use in hazardous environments (Zone 2) are installed in a DNV-certified 2.7-1 skid frame enclosure, and they generate 1000KVA at a power factor of 0.8, 400VAC, 3-phase +Neutral, and 60Hz output.

Diesel generator sets powered by diesel for use in Zone 2 hazardous areas are installed in DNV-certified 2.7-1 skid frame enclosures, producing 60KVA @ 0.8 power factor, 400VAC, 3-phase +Neutral, 50Hz output

For use in Hazardous Area (Zone 2), diesel-operated generator sets installed in the DNV-approved 2.7-1 Skid frame container, generating 400KVA @ 0.8 power factor, 400VAC, 3-Phase +Neutral, 50Hz/60Hz Output.

Diesel generator sets powered by diesel for use in a hazardous area (Zone 2) installed in a DNV-certified 2.7-1 skid frame container producing 30KVA @ 0.8 power factor, 400VAC, 3-phase +Neutral, 50Hz output.

Diesel driven generator sets for applications in Hazardous Area ( Zone 2 ) mounted in the DNV certified 2.7-1 Skid frame enclosure producing 190CFM Explosion-proof Air Compressor